LNS4

高硬度用 超硬4 枚刃 ロングネックスクエア防振エンドミル

LNS4

CATALOG PAGE NUMBER 39

不等分割・不等リード採用により

ビビりを抑制し高能率加工を実現!!

高硬度材~ HRC65 対応。

刃径公差 φ 2.0 ~φ 2.5 : 0 ~ -0.014

φ 3.0 ~φ 6.0 : 0 ~ -0.018

SIZE : φ 2 ~φ 6

スクロールできます

| 加工材質 | ブリハードン鋼 | 調質鋼 | 焼入れ鋼 |

|---|---|---|---|

| 硬度(HRC) | 〜45 | 40〜50 | 〜65 |

| 対応 | ◎ | ◎ | ◎ |

スペック

表示したいサイズをお選びください。

該当するスペックのみを表示します。

スクロールできます

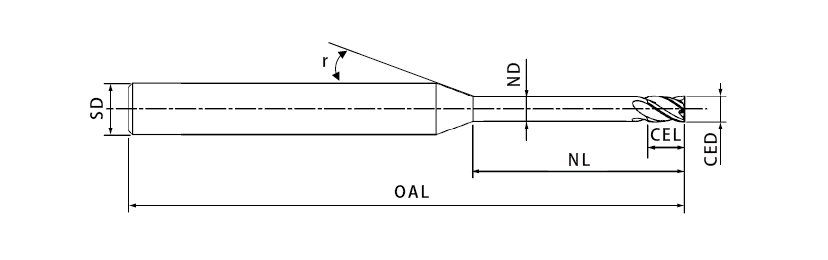

| 型番 | CED/ 刃径 | NL/ 首下長 | CEL/ 刃長 | ND/ 首径 | r / 首角 | SD/ シャンク径 | OAL/ 全長 | 販売価格/ ¥ |

|---|---|---|---|---|---|---|---|---|

| LNS4020-05-15 | 2 | 5 | 3 | 1.95 | 15° | 6 | 60 | 4,600 |

| LNS4020-10-15 | 2 | 10 | 3 | 1.95 | 15° | 6 | 60 | 4,600 |

| LNS4020-15-15 | 2 | 15 | 3 | 1.95 | 15° | 6 | 60 | 4,600 |

| LNS4020-20-15 | 2 | 20 | 3 | 1.95 | 15° | 6 | 60 | 4,600 |

| LNS4020-25-15 | 2 | 25 | 3 | 1.95 | 15° | 6 | 65 | 4,750 |

| LNS4020-30-15 | 2 | 30 | 3 | 1.95 | 15° | 6 | 75 | 5,120 |

| LNS4020-35-15 | 2 | 35 | 3 | 1.95 | 15° | 6 | 75 | 5,120 |

| LNS4025-15-15 | 2.5 | 15 | 3.8 | 2.45 | 15° | 6 | 60 | 4,600 |

| LNS4025-20-15 | 2.5 | 20 | 3.8 | 2.45 | 15° | 6 | 60 | 4,600 |

| LNS4025-25-15 | 2.5 | 25 | 3.8 | 2.45 | 15° | 6 | 65 | 4,750 |

| LNS4025-30-15 | 2.5 | 30 | 3.8 | 2.45 | 15° | 6 | 75 | 5,120 |

| LNS4025-40-15 | 2.5 | 40 | 3.8 | 2.45 | 15° | 6 | 100 | 6,030 |

| LNS4025-50-15 | 2.5 | 50 | 3.8 | 2.45 | 15° | 6 | 100 | 6,030 |

| LNS4030-20-15 | 3 | 20 | 4.5 | 2.85 | 15° | 6 | 60 | 4,600 |

| LNS4030-25-15 | 3 | 25 | 4.5 | 2.85 | 15° | 6 | 65 | 4,750 |

| LNS4030-30-15 | 3 | 30 | 4.5 | 2.85 | 15° | 6 | 75 | 5,120 |

| LNS4030-40-15 | 3 | 40 | 4.5 | 2.85 | 15° | 6 | 100 | 6,030 |

| LNS4030-50-15 | 3 | 50 | 4.5 | 2.85 | 15° | 6 | 100 | 6,030 |

| LNS4040-10-15 | 4 | 10 | 6 | 3.85 | 15° | 6 | 60 | 4,600 |

| LNS4040-15-15 | 4 | 15 | 6 | 3.85 | 15° | 6 | 60 | 4,600 |

| LNS4040-20-15 | 4 | 20 | 6 | 3.85 | 15° | 6 | 60 | 4,600 |

| LNS4040-25-15 | 4 | 25 | 6 | 3.85 | 15° | 6 | 65 | 4,750 |

| LNS4040-30-15 | 4 | 30 | 6 | 3.85 | 15° | 6 | 75 | 5,120 |

| LNS4040-35-15 | 4 | 35 | 6 | 3.85 | 15° | 6 | 75 | 5,120 |

| LNS4040-40-15 | 4 | 40 | 6 | 3.85 | 15° | 6 | 100 | 6,060 |

| LNS4040-45-15 | 4 | 45 | 6 | 3.85 | 15° | 6 | 100 | 6,060 |

| LNS4040-50-15 | 4 | 50 | 6 | 3.85 | 15° | 6 | 100 | 6,060 |

| LNS4060-10-15 | 6 | 10 | 9 | 5.85 | 15° | 6 | 60 | 4,600 |

| LNS4060-15-15 | 6 | 15 | 9 | 5.85 | 15° | 6 | 60 | 4,600 |

| LNS4060-20-15 | 6 | 20 | 9 | 5.85 | 15° | 6 | 60 | 4,600 |

| LNS4060-25-15 | 6 | 25 | 9 | 5.85 | 15° | 6 | 65 | 4,750 |

| LNS4060-30-15 | 6 | 30 | 9 | 5.85 | 15° | 6 | 75 | 5,120 |

| LNS4060-35-15 | 6 | 35 | 9 | 5.85 | 15° | 6 | 75 | 5,120 |

| LNS4060-40-15 | 6 | 40 | 9 | 5.85 | 15° | 6 | 100 | 6,030 |

| LNS4060-45-15 | 6 | 45 | 9 | 5.85 | 15° | 6 | 100 | 6,030 |

| LNS4060-50-15 | 6 | 50 | 9 | 5.85 | 15° | 6 | 100 | 6,030 |

切削条件参考表

スクロールできます

| 加工材質 | プリハードン鋼 | 調質鋼 | 焼入れ鋼 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 硬度 | ~ 40HRC | 40 ~ 50HRC | 50 ~ 65HRC | ||||||||||

| CED | NL | 回転数 | 送り | ap mm | ae mm | 回転 | 送り | ap mm | ae mm | 回転数 | 送り | ap mm | ae mm |

| 2 | 5 | 19,000 | 1,800 | 0.072 | 1.08 | 17,100 | 1,620 | 0.054 | 0.9 | 14,250 | 1,350 | 0.045 | 0.72 |

| 2 | 10 | 15,200 | 1,440 | 0.054 | 1.08 | 13,300 | 1,260 | 0.048 | 0.9 | 11,400 | 900 | 0.036 | 0.72 |

| 2 | 15 | 12,350 | 1,170 | 0.036 | 1.08 | 10,450 | 990 | 0.029 | 0.9 | 9,120 | 747 | 0.022 | 0.72 |

| 2 | 20 | 9,500 | 720 | 0.027 | 1.08 | 8,740 | 684 | 0.019 | 0.9 | 8,075 | 612 | 0.009 | 0.72 |

| 2 | 25 | 7,600 | 585 | 0.027 | 1.08 | 6,992 | 549 | 0.019 | 0.9 | 6,460 | 486 | 0.009 | 0.72 |

| 2 | 30 | 7,505 | 540 | 0.023 | 1.08 | 6,299 | 513 | 0.017 | 0.9 | 6,365 | 477 | 0.007 | 0.72 |

| 2 | 35 | 7,410 | 495 | 0.018 | 1.08 | 6,175 | 473 | 0.014 | 0.9 | 6,270 | 468 | 0.004 | 0.72 |

| 2.5 | 15 | 12,350 | 1,350 | 0.058 | 1.35 | 9,500 | 1,080 | 0.048 | 1.13 | 8,075 | 900 | 0.018 | 0.9 |

| 2.5 | 20 | 9,500 | 1,080 | 0.054 | 1.35 | 7,790 | 900 | 0.048 | 1.13 | 7,125 | 900 | 0.018 | 0.9 |

| 2.5 | 25 | 7,600 | 900 | 0.045 | 1.35 | 6,650 | 720 | 0.029 | 1.13 | 6,175 | 612 | 0.009 | 0.9 |

| 2.5 | 30 | 7,505 | 882 | 0.036 | 1.35 | 6,555 | 702 | 0.027 | 1.13 | 6,080 | 594 | 0.007 | 0.9 |

| 2.5 | 40 | 7,410 | 873 | 0.027 | 1.35 | 6,460 | 693 | 0.024 | 1.13 | 5,890 | 563 | 0.005 | 0.9 |

| 2.5 | 50 | 7,220 | 855 | 0.023 | 1.35 | 6,270 | 675 | 0.019 | 1.13 | 5,700 | 540 | 0.004 | 0.9 |

| 3 | 20 | 9,500 | 1,440 | 0.072 | 1.62 | 8,550 | 1,260 | 0.067 | 1.35 | 7,410 | 1,080 | 0.036 | 1.08 |

| 3 | 25 | 8,550 | 1,260 | 0.063 | 1.62 | 7,790 | 1,080 | 0.057 | 1.35 | 6,650 | 900 | 0.027 | 1.08 |

| 3 | 30 | 7,600 | 1,215 | 0.045 | 1.62 | 6,650 | 1,080 | 0.029 | 1.35 | 6,175 | 900 | 0.018 | 1.08 |

| 3 | 40 | 7,410 | 1,188 | 0.036 | 1.62 | 6,460 | 1,053 | 0.027 | 1.35 | 5,985 | 864 | 0.014 | 1.08 |

| 3 | 50 | 7,220 | 1,152 | 0.027 | 1.62 | 6,270 | 1,008 | 0.024 | 1.35 | 5,700 | 810 | 0.009 | 1.08 |

| 4 | 10 | 11,400 | 1,800 | 0.18 | 2.25 | 9,025 | 1,800 | 0.143 | 1.8 | 7,600 | 1,440 | 0.072 | 1.44 |

| 4 | 15 | 9,500 | 1,800 | 0.135 | 2.25 | 7,600 | 1,620 | 0.095 | 1.8 | 6,650 | 1,260 | 0.054 | 1.44 |

| 4 | 20 | 8,075 | 1,620 | 0.108 | 2.25 | 6,650 | 1,440 | 0.076 | 1.8 | 6,175 | 1,080 | 0.045 | 1.44 |

| 4 | 25 | 7,600 | 1,440 | 0.09 | 2.25 | 5,700 | 1,260 | 0.067 | 1.8 | 4,940 | 1,080 | 0.036 | 1.44 |

| 4 | 30 | 6,460 | 1,260 | 0.072 | 2.25 | 4,560 | 900 | 0.048 | 1.8 | 3,990 | 765 | 0.027 | 1.44 |

| 4 | 35 | 5,225 | 900 | 0.063 | 2.25 | 3,990 | 792 | 0.038 | 1.8 | 3,610 | 648 | 0.018 | 1.44 |

| 4 | 40 | 3,800 | 774 | 0.045 | 2.25 | 3,420 | 648 | 0.029 | 1.8 | 2,850 | 540 | 0.009 | 1.44 |

| 4 | 45 | 3,610 | 729 | 0.036 | 2.25 | 3,325 | 630 | 0.024 | 1.8 | 2,755 | 513 | 0.007 | 1.44 |

| 4 | 50 | 3,420 | 702 | 0.027 | 2.25 | 3,230 | 612 | 0.019 | 1.8 | 2,660 | 495 | 0.004 | 1.44 |

| 4 | 10 | 7,600 | 1,980 | 0.225 | 3.6 | 6,175 | 1,620 | 0.171 | 2.7 | 4,275 | 1,350 | 0.072 | 2.16 |

| 4 | 15 | 7,600 | 1,890 | 0.225 | 3.6 | 6,175 | 1,530 | 0.171 | 2.7 | 4,275 | 1,305 | 0.072 | 2.16 |

| 4 | 20 | 7,600 | 1,800 | 0.225 | 3.6 | 6,175 | 1,440 | 0.171 | 2.7 | 4,275 | 1,260 | 0.072 | 2.16 |

| 4 | 25 | 7,125 | 1,620 | 0.203 | 3.6 | 5,225 | 1,260 | 0.143 | 2.7 | 3,800 | 1,080 | 0.063 | 2.16 |

| 4 | 30 | 6,650 | 1,440 | 0.18 | 3.6 | 4,275 | 1,080 | 0.114 | 2.7 | 3,325 | 900 | 0.054 | 2.16 |

| 4 | 35 | 5,463 | 1,260 | 0.158 | 3.6 | 3,563 | 990 | 0.095 | 2.7 | 2,850 | 810 | 0.041 | 2.16 |

| 4 | 40 | 4,275 | 1,080 | 0.135 | 3.6 | 2,850 | 900 | 0.076 | 2.7 | 2,375 | 720 | 0.027 | 2.16 |

| 4 | 45 | 3,800 | 927 | 0.113 | 3.6 | 2,613 | 765 | 0.062 | 2.7 | 2,138 | 585 | 0.022 | 2.16 |

| 4 | 50 | 2,850 | 765 | 0.09 | 3.6 | 2,375 | 630 | 0.048 | 2.7 | 1,900 | 450 | 0.018 | 2.16 |

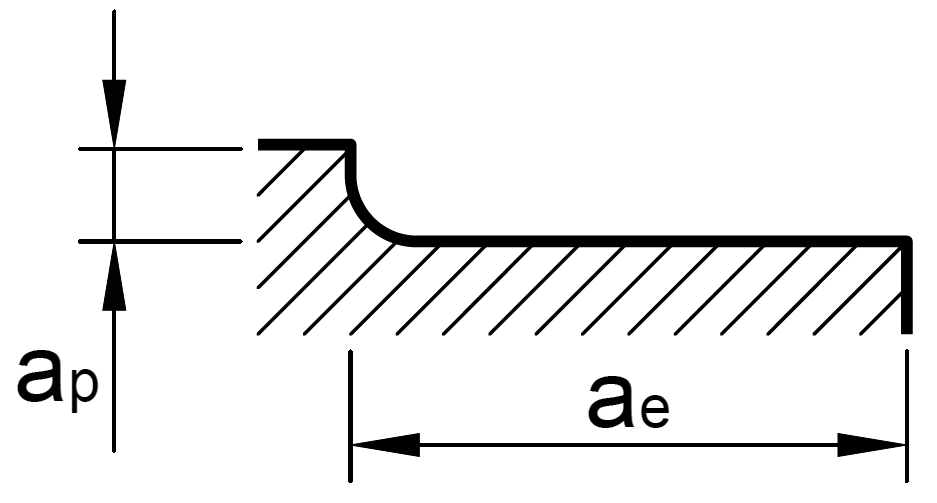

切込み深さ

ap=軸方向(縦方向)

ae=径方向

切削条件はあくまで目安であり作業環境の状況によって変動します。