BEHL4

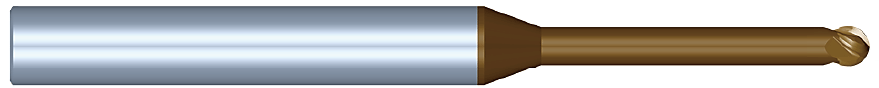

高硬度用 超硬4 枚刃 ロングネック防振ボールエンドミル

BEHL4

CATALOG PAGE NUMBER 47

不等分割・不等リード採用によりビビりを抑制し高能率加工を実現!!

高硬度材~ HRC65 対応。

R 精度: R3 ≧ ±0.005

R3 < ±0.008

SIZE :φ 1 ~φ 6

スクロールできます

| 加工材質 | ブリハードン鋼 | 調質鋼 | 焼入れ鋼 |

|---|---|---|---|

| 硬度(HRC) | 〜45 | 40〜50 | 〜65 |

| 対応 | ◎ | ◎ | ◎ |

スペック

表示したいサイズをお選びください。

該当するスペックのみを表示します。

スクロールできます

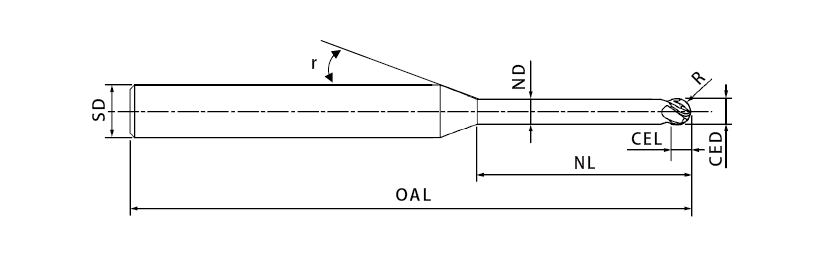

| 型番 | CED/ 刃径 | R | NL/ 首下長 | CEL/ 刃長 | ND/ 首径 | r / 首角 | SD/ シャンク径 | OAL/ 全長販 | 売価格/ ¥ |

|---|---|---|---|---|---|---|---|---|---|

| BEHL4010-05-08 | 1 | R0.5 | 5 | 0.8 | 0.95 | 15° | 6 | 60 | 5,270 |

| BEHL4010-10-08 | 1 | R0.5 | 10 | 0.8 | 0.95 | 15° | 6 | 60 | 5,270 |

| BEHL4010-15-08 | 1 | R0.5 | 15 | 0.8 | 0.95 | 15° | 6 | 60 | 5,270 |

| BEHL4010-20-08 | 1 | R0.5 | 20 | 0.8 | 0.95 | 15° | 6 | 60 | 5,270 |

| BEHL4015-05-12 | 1.5 | R0.75 | 5 | 1.2 | 1.45 | 15° | 6 | 60 | 5,270 |

| BEHL4015-10-12 | 1.5 | R0.75 | 10 | 1.2 | 1.45 | 15° | 6 | 60 | 5,270 |

| BEHL4015-15-12 | 1.5 | R0.75 | 15 | 1.2 | 1.45 | 15° | 6 | 60 | 5,270 |

| BEHL4015-20-12 | 1.5 | R0.75 | 20 | 1.2 | 1.45 | 15° | 6 | 60 | 5,270 |

| BEHL4020-05-16 | 2 | R1 | 5 | 1.6 | 1.95 | 15° | 6 | 60 | 5,150 |

| BEHL4020-10-16 | 2 | R1 | 10 | 1.6 | 1.95 | 15° | 6 | 60 | 5,150 |

| BEHL4020-15-16 | 2 | R1 | 15 | 1.6 | 1.95 | 15° | 6 | 60 | 5,150 |

| BEHL4020-20-16 | 2 | R1 | 20 | 1.6 | 1.95 | 15° | 6 | 60 | 5,150 |

| BEHL4020-25-16 | 2 | R1 | 25 | 1.6 | 1.95 | 15° | 6 | 65 | 5,380 |

| BEHL4020-30-16 | 2 | R1 | 30 | 1.6 | 1.95 | 15° | 6 | 75 | 5,730 |

| BEHL4020-35-16 | 2 | R1 | 35 | 1.6 | 1.95 | 15° | 6 | 75 | 5,730 |

| BEHL4030-10-24 | 3 | R1.5 | 10 | 2.4 | 2.85 | 15° | 6 | 60 | 5,150 |

| BEHL4030-15-24 | 3 | R1.5 | 15 | 2.4 | 2.85 | 15° | 6 | 60 | 5,150 |

| BEHL4030-20-24 | 3 | R1.5 | 20 | 2.4 | 2.85 | 15° | 6 | 60 | 5,150 |

| BEHL4030-25-24 | 3 | R1.5 | 25 | 2.4 | 2.85 | 15° | 6 | 65 | 5,380 |

| BEHL4030-30-24 | 3 | R1.5 | 30 | 2.4 | 2.85 | 15° | 6 | 75 | 5,730 |

| BEHL4030-35-24 | 3 | R1.5 | 35 | 2.4 | 2.85 | 15° | 6 | 75 | 5,730 |

| BEHL4030-40-24 | 3 | R1.5 | 40 | 2.4 | 2.85 | 15° | 6 | 100 | 5,850 |

| BEHL4035-10-28 | 3.5 | R1.75 | 10 | 2.8 | 3.35 | 15° | 6 | 60 | 5,150 |

| BEHL4035-15-28 | 3.5 | R1.75 | 15 | 10 | 2.8 | 3.35 | 6 | 60 | 5,150 |

| BEHL4035-20-28 | 3.5 | R1.75 | 20 | 10 | 2.8 | 3.35 | 6 | 60 | 5,150 |

| BEHL4035-25-28 | 3.5 | R1.75 | 25 | 10 | 2.8 | 3.35 | 6 | 65 | 5,380 |

| BEHL4035-30-28 | 3.5 | R1.75 | 30 | 10 | 2.8 | 3.35 | 6 | 75 | 5,730 |

| BEHL4035-35-28 | 3.5 | R1.75 | 35 | 10 | 2.8 | 3.35 | 6 | 75 | 5,730 |

| BEHL4035-40-28 | 3.5 | R1.75 | 40 | 10 | 2.8 | 3.35 | 6 | 100 | 6,700 |

| BEHL4035-45-28 | 3.5 | R1.75 | 45 | 10 | 2.8 | 3.35 | 6 | 100 | 6,700 |

| BEHL4040-10-32 | 4 | R2 | 10 | 3.2 | 3.85 | 15° | 6 | 60 | 5,150 |

| BEHL4040-15-32 | 4 | R2 | 15 | 3.2 | 3.85 | 15° | 6 | 60 | 5,150 |

| BEHL4040-20-32 | 4 | R2 | 20 | 3.2 | 3.85 | 15° | 6 | 60 | 5,150 |

| BEHL4040-25-32 | 4 | R2 | 25 | 3.2 | 3.85 | 15° | 6 | 65 | 5,380 |

| BEHL4040-30-32 | 4 | R2 | 30 | 3.2 | 3.85 | 15° | 6 | 75 | 5,730 |

| BEHL4040-35-32 | 4 | R2 | 35 | 3.2 | 3.85 | 15° | 6 | 75 | 5,730 |

| BEHL4040-40-32 | 4 | R2 | 40 | 3.2 | 3.85 | 15° | 6 | 100 | 6,700 |

| BEHL4040-45-32 | 4 | R2 | 45 | 3.2 | 3.85 | 15° | 6 | 100 | 6,700 |

| BEHL4040-50-32 | 4 | R2 | 50 | 3.2 | 3.85 | 15° | 6 | 100 | 6,700 |

| BEHL4050-10-50 | 5 | R2.5 | 10 | 5 | 4.85 | 15° | 6 | 60 | 5,150 |

| BEHL4050-15-50 | 5 | R2.5 | 15 | 5 | 4.85 | 15° | 6 | 60 | 5,150 |

| BEHL4050-20-50 | 5 | R2.5 | 20 | 5 | 4.85 | 15° | 6 | 60 | 5,150 |

| BEHL4050-25-50 | 5 | R2.5 | 25 | 5 | 4.85 | 15° | 6 | 65 | 5,380 |

| BEHL4050-30-50 | 5 | R2.5 | 30 | 5 | 4.85 | 15° | 6 | 75 | 5,730 |

| BEHL4050-35-50 | 5 | R2.5 | 35 | 5 | 4.85 | 15° | 6 | 75 | 5,730 |

| BEHL4050-40-50 | 5 | R2.5 | 40 | 5 | 4.85 | 15° | 6 | 100 | 6,700 |

| BEHL4050-45-50 | 5 | R2.5 | 45 | 5 | 4.85 | 15° | 6 | 100 | 6,700 |

| BEHL4050-50-50 | 5 | R2.5 | 50 | 5 | 4.85 | 15° | 6 | 100 | 6,700 |

| BEHL4060-10-60 | 6 | R3 | 10 | 6 | 5.85 | 15° | 6 | 60 | 5,150 |

| BEHL4060-15-60 | 6 | R3 | 15 | 6 | 5.85 | 15° | 6 | 60 | 5,150 |

| BEHL4060-20-60 | 6 | R3 | 20 | 6 | 5.85 | 15° | 6 | 60 | 5,150 |

| BEHL4060-25-60 | 6 | R3 | 25 | 6 | 5.85 | 15° | 6 | 65 | 5,380 |

| BEHL4060-30-60 | 6 | R3 | 30 | 6 | 5.85 | 15° | 6 | 75 | 5,730 |

| BEHL4060-35-60 | 6 | R3 | 35 | 6 | 5.85 | 15° | 6 | 75 | 5,730 |

| BEHL4060-40-60 | 6 | R3 | 40 | 6 | 5.85 | 15° | 6 | 100 | 6,700 |

| BEHL4060-45-60 | 6 | R3 | 45 | 6 | 5.85 | 15° | 6 | 100 | 6,700 |

| BEHL4060-50-60 | 6 | R3 | 50 | 6 | 5.85 | 15° | 6 | 100 | 6,700 |

切削条件参考表

スクロールできます

| 加工材質 | プリハードン鋼 | 調質鋼 | 焼入れ鋼 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 硬度 | ~ 40HRC | 40 ~ 50HRC | 50 ~ 65HRC | |||||||||||

| CED | R | NL | 回転数 | 送り | ap mm | ae mm | 回転 | 送り | ap mm | ae mm | 回転数 | 送り | ap mm | ae mm |

| 1 | 0.5R | 5 | 41,040 | 1,890 | 0.045 | 0.09 | 41,040 | 1,440 | 0.045 | 0.09 | 41,040 | 1,080 | 0.018 | 0.045 |

| 1 | 0.5R | 10 | 25,080 | 900 | 0.009 | 0.018 | 23,940 | 684 | 0.009 | 0.018 | 20,520 | 468 | 0.009 | 0.018 |

| 1 | 0.5R | 15 | 19,380 | 437 | 0.005 | 0.009 | 18,240 | 329 | 0.005 | 0.009 | 15,960 | 225 | 0.005 | 0.009 |

| 1 | 0.5R | 20 | 14,820 | 257 | 0.005 | 0.004 | 13,680 | 162 | 0.005 | 0.005 | 13,680 | 126 | 0.004 | 0.005 |

| 1.5 | 0.75R | 5 | 39,900 | 2,880 | 0.068 | 0.135 | 39,900 | 2,340 | 0.068 | 0.135 | 37,620 | 1,710 | 0.027 | 0.054 |

| 1.5 | 0.75R | 10 | 27,360 | 1,710 | 0.068 | 0.135 | 27,360 | 1,350 | 0.068 | 0.135 | 20,520 | 612 | 0.027 | 0.054 |

| 1.5 | 0.75R | 15 | 17,670 | 554 | 0.045 | 0.09 | 17,100 | 657 | 0.045 | 0.09 | 14,250 | 437 | 0.027 | 0.054 |

| 1.5 | 0.75R | 20 | 13,680 | 306 | 0.018 | 0.045 | 12,540 | 216 | 0.018 | 0.045 | 9,310 | 117 | 0.018 | 0.045 |

| 2 | 1R | 5 | 45,600 | 4,050 | 0.09 | 0.18 | 44,460 | 3,870 | 0.09 | 0.18 | 38,760 | 2,430 | 0.045 | 0.09 |

| 2 | 1R | 10 | 22,800 | 1,980 | 0.09 | 0.18 | 21,660 | 1,800 | 0.09 | 0.18 | 19,380 | 1,260 | 0.045 | 0.09 |

| 2 | 1R | 15 | 16,530 | 1,485 | 0.09 | 0.135 | 15,390 | 1,305 | 0.09 | 0.135 | 13,110 | 878 | 0.045 | 0.09 |

| 2 | 1R | 20 | 12,540 | 990 | 0.045 | 0.09 | 11,400 | 801 | 0.045 | 0.09 | 10,260 | 576 | 0.045 | 0.09 |

| 2 | 1R | 25 | 10,260 | 684 | 0.027 | 0.045 | 10,260 | 612 | 0.027 | 0.045 | 8,550 | 405 | 0.027 | 0.045 |

| 2 | 1R | 30 | 10,260 | 423 | 0.018 | 0.045 | 10,260 | 324 | 0.018 | 0.045 | 8,550 | 216 | 0.018 | 0.045 |

| 2 | 1R | 35 | 8,550 | 207 | 0.018 | 0.027 | 7,980 | 117 | 0.018 | 0.027 | 6,840 | 90 | 0.018 | 0.027 |

| 3 | 1.5R | 10 | 22,800 | 2,520 | 0.135 | 0.27 | 20,520 | 2,250 | 0.135 | 0.27 | 18,240 | 1,530 | 0.054 | 0.135 |

| 3 | 1.5R | 15 | 18,240 | 1,980 | 0.09 | 0.27 | 14,820 | 1,620 | 0.09 | 0.27 | 12,540 | 1,080 | 0.054 | 0.135 |

| 3 | 1.5R | 20 | 15,960 | 1,530 | 0.09 | 0.18 | 12,540 | 1,440 | 0.09 | 0.18 | 11,400 | 900 | 0.054 | 0.135 |

| 3 | 1.5R | 25 | 13,680 | 990 | 0.045 | 0.09 | 10,260 | 738 | 0.045 | 0.09 | 9,120 | 522 | 0.045 | 0.09 |

| 3 | 1.5R | 30 | 10,260 | 684 | 0.027 | 0.045 | 7,980 | 531 | 0.027 | 0.045 | 6,840 | 360 | 0.027 | 0.045 |

| 3 | 1.5R | 35 | 8,550 | 513 | 0.018 | 0.045 | 6,840 | 414 | 0.018 | 0.045 | 5,700 | 270 | 0.018 | 0.045 |

| 3 | 1.5R | 40 | 7,410 | 423 | 0.018 | 0.027 | 5,700 | 324 | 0.018 | 0.027 | 4,560 | 207 | 0.018 | 0.027 |

| 3.5 | 1.75R | 10 | 22,800 | 2,790 | 0.09 | 0.27 | 18,240 | 1,980 | 0.09 | 0.27 | 15,960 | 1,350 | 0.063 | 0.135 |

| 3.5 | 1.75R | 15 | 20,520 | 2,520 | 0.09 | 0.27 | 15,960 | 1,800 | 0.09 | 0.27 | 13,680 | 1,170 | 0.063 | 0.135 |

| 3.5 | 1.75R | 20 | 18,240 | 2,250 | 0.09 | 0.18 | 13,680 | 1,620 | 0.09 | 0.18 | 11,400 | 1,080 | 0.063 | 0.135 |

| 3.5 | 1.75R | 25 | 13,680 | 1,710 | 0.09 | 0.09 | 10,260 | 1,170 | 0.09 | 0.09 | 9,120 | 828 | 0.063 | 0.135 |

| 3.5 | 1.75R | 30 | 11,400 | 1,350 | 0.045 | 0.09 | 9,120 | 990 | 0.045 | 0.09 | 7,980 | 693 | 0.045 | 0.09 |

| 3.5 | 1.75R | 35 | 10,260 | 855 | 0.045 | 0.045 | 7,980 | 630 | 0.045 | 0.045 | 5,700 | 360 | 0.045 | 0.045 |

| 3.5 | 1.75R | 40 | 8,550 | 684 | 0.045 | 0.045 | 6,840 | 522 | 0.045 | 0.045 | 4,560 | 270 | 0.045 | 0.045 |

| 3.5 | 1.75R | 45 | 7,410 | 513 | 0.027 | 0.027 | 5,700 | 378 | 0.027 | 0.027 | 4,560 | 234 | 0.027 | 0.027 |

| 4 | 2R | 10 | 28,500 | 3,780 | 0.18 | 0.45 | 22,800 | 2,970 | 0.18 | 0.45 | 20,520 | 2,070 | 0.072 | 0.18 |

| 4 | 2R | 15 | 22,800 | 3,060 | 0.18 | 0.45 | 18,240 | 2,430 | 0.18 | 0.45 | 13,680 | 1,440 | 0.072 | 0.18 |

| 4 | 2R | 20 | 18,240 | 2,340 | 0.18 | 0.36 | 15,960 | 2,070 | 0.18 | 0.36 | 9,120 | 900 | 0.072 | 0.18 |

| 4 | 2R | 25 | 18,240 | 2,340 | 0.09 | 0.27 | 14,820 | 1,980 | 0.09 | 0.27 | 6,840 | 729 | 0.072 | 0.18 |

| 4 | 2R | 30 | 15,960 | 1,980 | 0.09 | 0.18 | 13,680 | 1,710 | 0.09 | 0.18 | 5,700 | 567 | 0.072 | 0.18 |

| 4 | 2R | 35 | 13,680 | 1,530 | 0.09 | 0.18 | 10,260 | 1,080 | 0.09 | 0.18 | 4,560 | 378 | 0.072 | 0.18 |

| 4 | 2R | 40 | 10,260 | 1,080 | 0.045 | 0.09 | 9,120 | 900 | 0.045 | 0.09 | 4,560 | 360 | 0.045 | 0.09 |

| 4 | 2R | 45 | 8,550 | 855 | 0.045 | 0.045 | 7,980 | 801 | 0.045 | 0.045 | 4,180 | 324 | 0.045 | 0.045 |

| 50 | 7,410 | 594 | 0.018 | 0.045 | 6,840 | 540 | 0.018 | 0.045 | 4,180 | 252 | 0.018 | 0.045 | ||

| 5 | 2.5R | 10 | 28,500 | 4,860 | 0.225 | 0.45 | 21,660 | 3,600 | 0.225 | 0.45 | 18,240 | 2,520 | 0.09 | 0.225 |

| 5 | 2.5R | 15 | 22,800 | 3,510 | 0.225 | 0.45 | 19,380 | 2,970 | 0.225 | 0.45 | 14,820 | 1,800 | 0.09 | 0.225 |

| 5 | 2.5R | 20 | 18,240 | 2,970 | 0.225 | 0.45 | 14,820 | 2,430 | 0.225 | 0.45 | 9,120 | 1,170 | 0.09 | 0.225 |

| 5 | 2.5R | 25 | 17,100 | 2,700 | 0.18 | 0.27 | 13,680 | 2,160 | 0.18 | 0.27 | 6,840 | 864 | 0.09 | 0.225 |

| 5 | 2.5R | 30 | 15,960 | 2,070 | 0.09 | 0.27 | 12,540 | 1,620 | 0.09 | 0.27 | 4,560 | 468 | 0.09 | 0.225 |

| 5 | 2.5R | 35 | 13,680 | 1,350 | 0.09 | 0.27 | 11,400 | 990 | 0.09 | 0.27 | 3,705 | 252 | 0.09 | 0.225 |

| 5 | 2.5R | 40 | 11,400 | 990 | 0.09 | 0.18 | 10,260 | 891 | 0.09 | 0.18 | 3,420 | 234 | 0.09 | 0.18 |

| 5 | 2.5R | 45 | 10,260 | 765 | 0.09 | 0.09 | 9,120 | 594 | 0.09 | 0.09 | 3,420 | 180 | 0.09 | 0.09 |

| 5 | 2.5R | 50 | 8,550 | 684 | 0.09 | 0.09 | 7,980 | 549 | 0.09 | 0.09 | 3,230 | 171 | 0.09 | 0.09 |

| 6 | 3R | 10 | 25,080 | 5,040 | 0.27 | 0.45 | 20,520 | 3,420 | 0.27 | 0.45 | 17,670 | 2,520 | 0.09 | 0.18 |

| 6 | 3R | 15 | 21,090 | 4,320 | 0.27 | 0.45 | 16,530 | 2,925 | 0.27 | 0.45 | 13,680 | 1,665 | 0.09 | 0.18 |

| 6 | 3R | 20 | 18,240 | 3,510 | 0.27 | 0.45 | 13,680 | 2,700 | 0.27 | 0.45 | 9,120 | 1,440 | 0.09 | 0.18 |

| 6 | 3R | 25 | 13,680 | 2,700 | 0.27 | 0.45 | 11,400 | 2,250 | 0.27 | 0.45 | 6,840 | 1,080 | 0.09 | 0.18 |

| 6 | 3R | 30 | 11,400 | 2,160 | 0.27 | 0.45 | 10,260 | 1,890 | 0.27 | 0.45 | 4,560 | 666 | 0.09 | 0.18 |

| 6 | 3R | 35 | 10,260 | 1,890 | 0.18 | 0.36 | 10,260 | 1,800 | 0.18 | 0.36 | 3,990 | 558 | 0.09 | 0.18 |

| 6 | 3R | 40 | 10,260 | 1,710 | 0.18 | 0.27 | 10,260 | 1,620 | 0.18 | 0.27 | 3,420 | 432 | 0.09 | 0.18 |

| 6 | 3R | 45 | 9,120 | 1,530 | 0.18 | 0.27 | 9,120 | 1,440 | 0.18 | 0.27 | 3,230 | 396 | 0.09 | 0.18 |

| 6 | 3R | 50 | 7,980 | 1,350 | 0.18 | 0.27 | 7,980 | 1,260 | 0.18 | 0.27 | 2,850 | 360 | 0.09 | 0.18 |

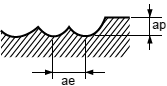

ap=軸方向(縦方向)

ae=径方向

切削条件はあくまで目安であり作業環境の状況によって変動します。